Large-Scale Potato Starch Production: Recommended Equipment for Wet Process Technology

10-29,2025 / FAQ / Chat online / Leave a message

- TEL:

- WhatsApp:

- Email:

market@doingmachinery.com

For large-scale potato starch production, wet process technology remains the industry standard for achieving high starch yield, purity, and processing efficiency. This method, which separates starch granules from potato cells in a water-based system, is particularly suited for automated production lines handling 20 tons or more of raw potatoes daily. Below is an overview of the essential equipment required for a fully integrated, large-scale potato starch production line.

Essential Equipment for an Automated Potato Starch Wet Process Line

1. Raw Material Handling and Washing Unit

Primary Function: Removal of soil, stones, and organic impurities from raw potatoes.

Key Equipment:

Dry Sieve: Handle large impurities like soil, stones, leaves on raw potatoes.

Rotary Washer: Provide thorough scrubbing and washing potatoes through rotational movement in a water medium.

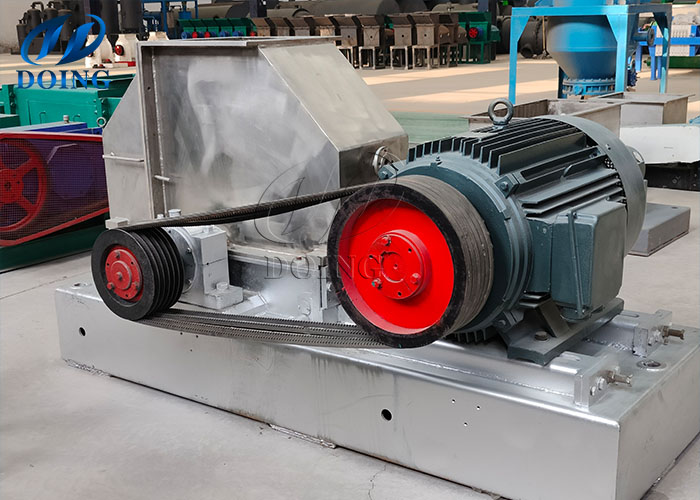

2. Cutting and Grinding Unit

Primary Function: Disintegration of potato tissue to release starch granules.

Key Equipment:

Cutting Machine: Cut potatoes into small pieces convenient for further grinding

High-Capacity Raspers: Feature specially designed saw blades to create uniform pulp consistency while maximizing potato starch release.

cassava rasper

cassava rasper

3. Starch Extraction and Separation Unit

Primary Function: Separation of potato starch milk from fibrous pulp.

Key Equipment:

Centrifugal Sieve: Multi-stage screening systems that separate potato starch from fiber through counter-current washing principles.

4. Starch Purification Unit

Primary Function: Further removal of residual impurities like proteins and cell saps and other soluble components.

Key Equipment:

Desanding Cyclones: Specifically designed for removing mineral impurities.

Multi-Stage Hydrocyclone Stations: Provide efficient washing and concentration of starch. Refine starch milk by removing proteins and fine impurities through density-based separation.

hydrocyclone station

hydrocyclone station

5. Dewatering Unit

Primary Function: Reduction of moisture content in purified potato starch slurry.

Key Equipment:

Vacuum Filtration Units: Employ vacuum pressure to extract water from starch slurry, forming a moist cake with reduced moisture content of 40%.

6. Drying System

Primary Function: Final moisture reduction to meet commercial standards.

Key Equipment:

Flash Dryer: Utilize rapid hot air exposure to efficiently dry starch particles without compromising quality. Normally the moisture of dry potato starch is about 12-14%

Cooling Conveyors: Stabilize potato starch temperature post-drying.

flash dryer

flash dryer

7. Finishing and Packaging Unit

Primary Function: Preparation of qualified potato starch for storage and distribution.

Key Equipment:

Milling and Sieving Systems: Ensure uniform particle size distribution.

Automated Packaging Machines: Provide precise weighing and packaging operations.

Technical Advantages of Potato Starch Wet Process Technology

Enhanced Starch Recovery: Achieves superior extraction rates through comprehensive cell rupture and counter-current washing.

Consistent Quality Output: Multi-stage refining ensures high purity and uniform product characteristics.

Processing Efficiency: Continuous operation capability supports high-volume throughput requirements.

Resource Optimization: Closed-water systems minimize fresh water consumption through sophisticated recycling.

The wet process technology, incorporating specialized equipment from initial washing through final drying, represents the optimal solution for large-scale potato starch production. Tell us your capacity, Henan Jinrui's engineers will design a tailed equipment design!

contact us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

Call us

Call us Chat online

Chat online