Peeler centrifuge

02-26,2022 / Cassava machine / Chat online / Leave a message

- TEL:

- WhatsApp:

- Email:

market@doingmachinery.com

The introduction of peeler centrifuge

Peeler centrifuge is a filter centrifuge which adodpts continuous running and intermittent discharging. Its control mode is automatic control, or manual control. In the process of operation, feeding, separation, washing, dehydration, discharging, regeneration of filter cloth and other general process are completed under full throttle. It has the features of short single cycle time, large capacity and good washing effect. Peeler centrifuge is widely used in chemical, food, light industry, pharmacy, starch industry, etc. It is suitable for suspension containing coarse, medium and fine particles, such as ammonium carbide, polyvinyl chloride, modified starch, etc.

In cassava starch production industry, peeler centrifuge can be used together with vacuum filter for dehydration of starch slurry. By using peeler centrifuge sieve after vacuum filter, the production capacity of starch is increased by 50% and the moisture content is decreased to 36.5%.

Peeler centrifuge

Peeler centrifuge

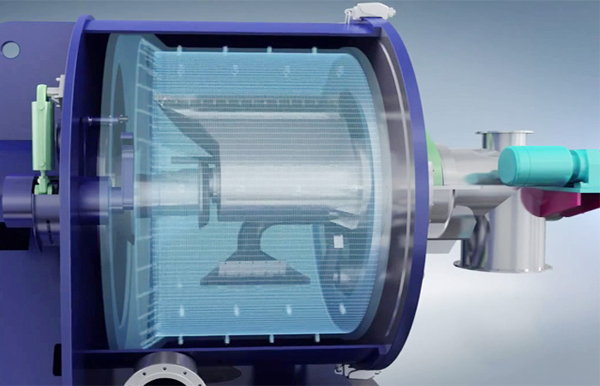

The structure and working principle

The peeler centrifuge is composed of the following:1. Scraper screw assembly 2. Bracket components 3. Rotary components 4. Siphon components 5. Unit components 6. Transmission components 7. Oil supply system

When working, the main motor of the peeler centrifuge drives the inner and outer drum of the machine to rotate at full speed. Under the effect of centrifugal force, the liquid content goes through the filter cloth and filter hole of inner drum wall and is discharged out of the inner drum. Then the discharged liquid content is collected into the gap between inner and outer rotary drum and then it goes through the siphon hole into the siphon chamber. And finally the liquid is pumped out of the device by a siphon device. While the solid phase is retained in the inner drum to form a circular filter cake layer. After the feeding reaches the predetermined volume, the feeding is stopped. And then is the separation and washing. After washing and separating, the scraper rotates automatically, scraping the solid phase down through the feed screw out of the machine, and then washing the net automatically to start the next cycle.

Structure of peeler centrifuge

Structure of peeler centrifuge

The technical parameters of peeler centrifuge

| Model | GK-800N | GK(H)-1250(EW) | GK(H)-1600N |

| Filter area(m2) | 1.13 | 2.36 | 4.68 |

| Maximum load(kg) | 150 | 450 | 996 |

| Maximun load(L) | 100 | 355 | 830 |

| Material | Stainless steel | Stainless steel | Stainless steel |

| Bowl diameter(mm) | 800 | 1250 | 1600 |

| Bowl length(mm) | 450 | 600 | 1000 |

| Rotating speed(r/min) | 1550 | 1200 | 950 |

| Separating factor | 1070 | 1006 | 808 |

| Dimension(mm) | 2030*1960*1530 | 2870*2470*1955 | 4050*2745*2295 |

| Weight(kg) | 5500 | 11150 | 16550 |

| Power(kw) | 45 | 90 | 132 |

Peeler centrifuge for cassava processing

Peeler centrifuge for cassava processing

The features of peeler centrifuge

1. This machine is designed with Programmable controller control, program setting and unattended automatic operation, which can achieve man-machine dialogue, so that it is easy to operate and convenience to maintain.

2. The electric-hydraulic automatic control can realize the monitoring of the whole process of feeding, primary filtering, washing, fine filtering and discharging.

3. The peeler centrifuge adopts the principle of siphon, with high production efficiency. Increase production capacity by 50% and reduce moisture content to 36.5%.

4. This peeler centrifuge is equipped with a backwashing device, which can reverse flush and soak the residual filter cake layer in the drum, so as to regenerate the filter cloth.

Peeler centrifuge

Peeler centrifuge

The advantages of peeler centrifuge

1.The materials that the peeler centrifuge contacts with the separation medium are all made of stainless steel, which improves the corrosion resistance and hygiene requirements of the machine.

2. The machine runs smoothly which greatly reduces vibration and noise, so that the production workshop and working environment are improved, and the damage of machine vibration to equipment and environment is reduced.

3. The motor and centrifuge body are installed as a whole, which is convenient for users to install and use, and reduces the occupation of the device.

4. Fully enclosed structure and convenient adjustment and maintenance.

5. Small size, high efficiency and long service life.

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

Call us

Call us Chat online

Chat online